Long-distance Quality Control? No problem!

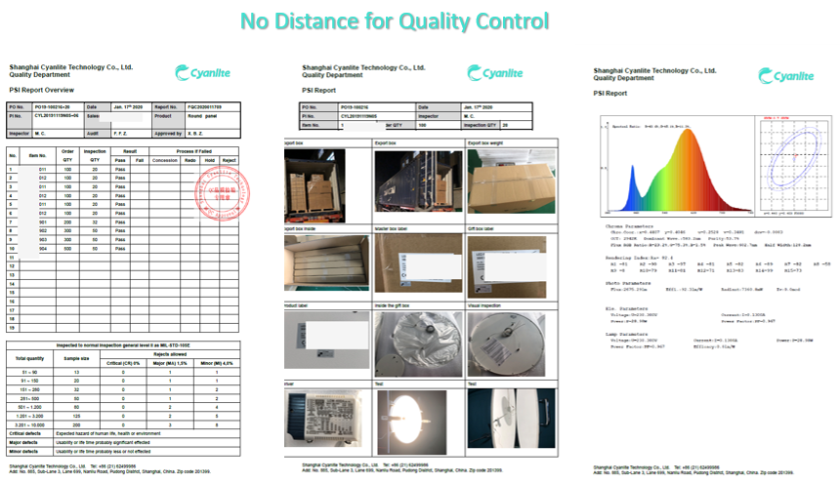

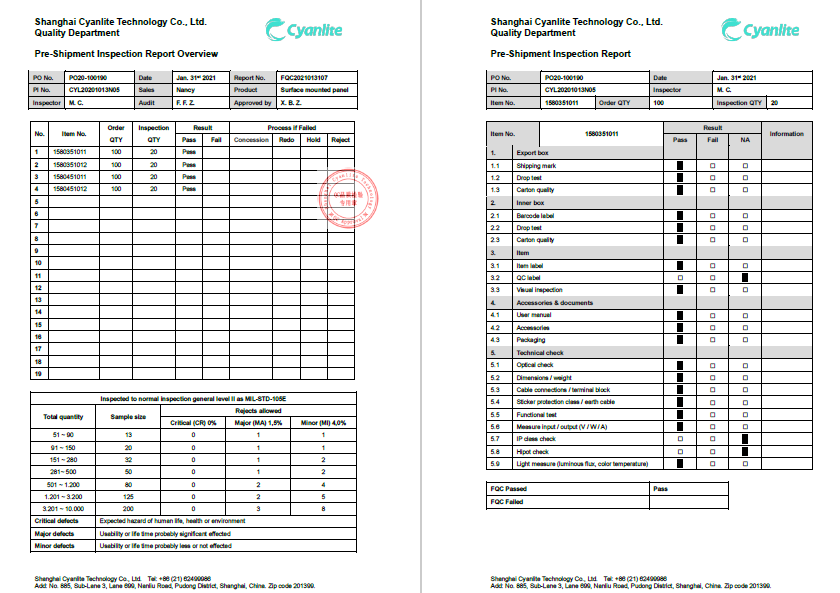

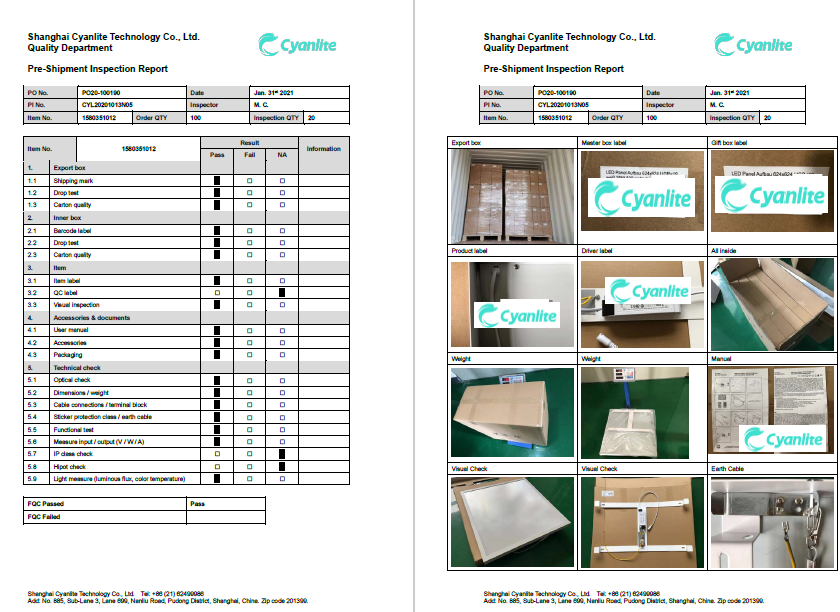

To make sure the quality standard is met, Cyanlite implements rigorous inspection and provide the detailed Pre-shipment Inspection Report to our customers for every single shipment, offering our clients an objective review of the products and with the perspective like you or your inspector are right there to implement the inspection, and you know what you will have before receiving them.

How we do it?

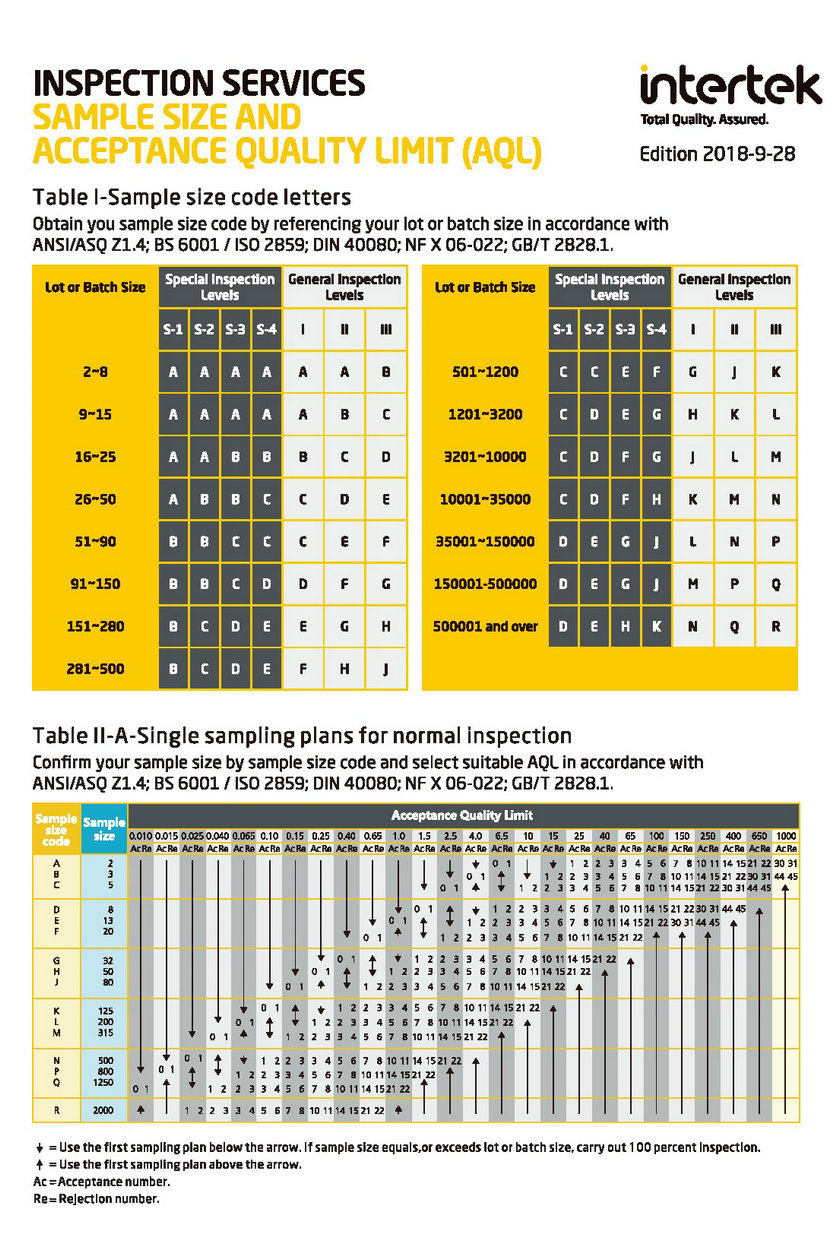

Firstly, according to MIL-STD-105E (in accordance with AN5I/A5Q 21.4; B5 6001 / 150 2859; DIN 40080; NF X 06-022; GB/T 2828.1.), we’ll choose the sample size based on the total quantity of each item.

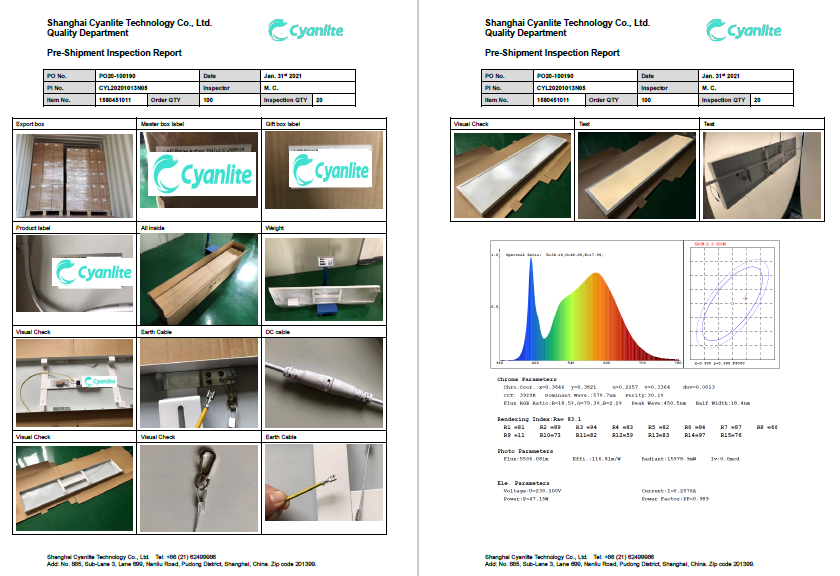

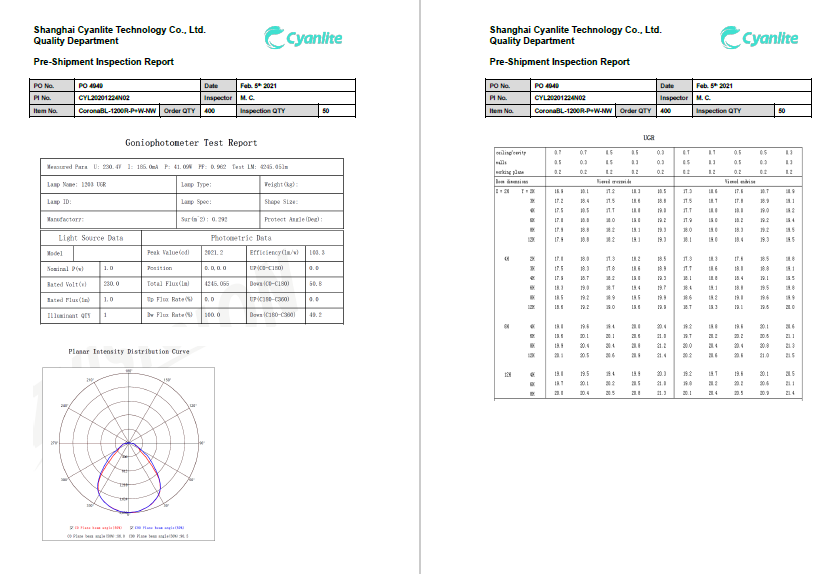

Here's a sneak peek of our typical PSI report.

For more details, feel free to request a Pre-shipment Inspection Report sample from our sales guy, contact now!

All Cyanlite Products are at least 5 years warranty, please check our warranty letter here:

https://www.cyanlite.com/download/Cyanlite-Products-Warranty-Letter.html

+86 21 3157 9659-839

SEND EMAIL

Name: Jim Wang

Mobile:+86-131 6619 3993

Tel:+86-21-3157 9655

Email:sales@cyanlite.com

Add:No.93 Jianhao Road, Pudong District, Shanghai 201318, China